AT FIRST

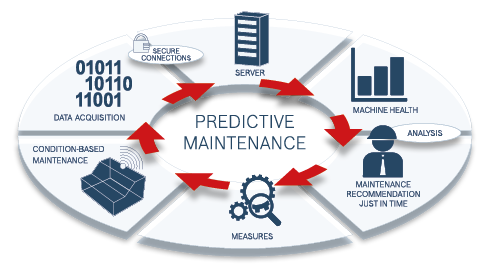

PREDICTIVE MAINTENANCE

- Simple data exchange with third-party systems

- Open for HMI expansions

- Ready for the communication with any Open Platform Communication UA servers and Clients (control units, drives, sensors, MES, etc.)

- Easy implementation of additional/machine learning algorithms

- Predefined and adaptable solutions for machine and production specific tasks

- Continuous data transfer into the database

OPTIONS

In our service packages, you will find a solution tailored exactly to your condition-based maintenance needs. Rexroth Service supervises the wear of components, modules and fluids with several Condition Monitoring Tools. Data will be provided on a secure server by latest sensor technology. Thus it’s possible, to conduct custom tailored analyses referred to the current state of the machine and initiate necessary maintenance measures. A wide range of service agreements can complete the secure maintenance.

OPTIONS

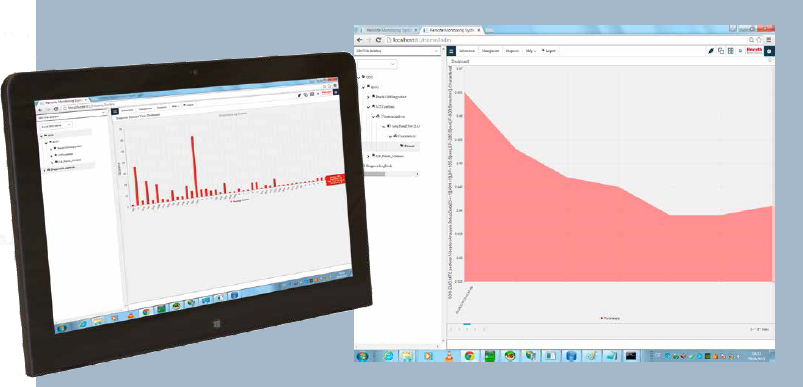

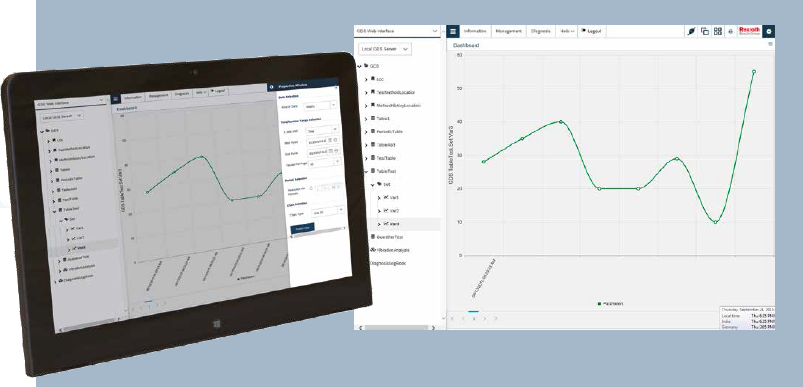

CONDITION MONITORING

PROCESS MONITORING

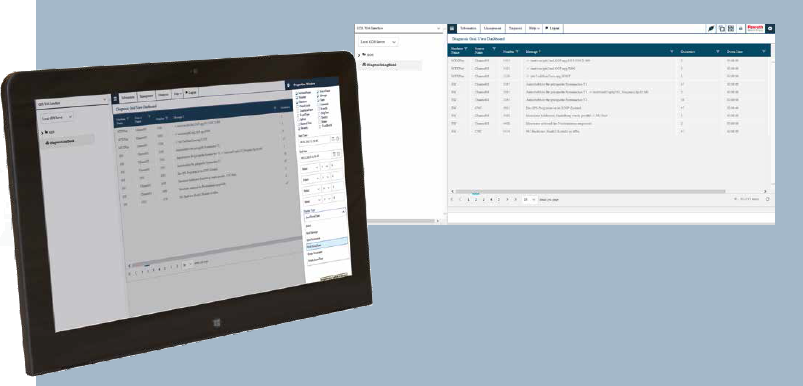

LONGTERM DIAGNOSIS LOGBOOK

Every machine has a characteristic normal behavior, which depends on many factors, such as machine type, built-in components, dynamic operation, produced product, environment etc.

ADVANTAGES